703 2nd St Ste 445, Santa Rosa, CA, United States of America, 95404

Feeds

.jpg)

Fermentation in Flux: How MSP Data Reveals Temperature Stratification Challenges

Tank temperature stratification doesn't differ in the Southern Hemisphere!

Tank temperature stratification doesn't differ in the Southern Hemisphere!

We have a new MSP deployment and the data shows there are TWO different fermentations happening in ONE tank. Unfortunately fermenting Bordeaux at 14C/57F lower in the tank and 30C/86F near the top is likely not the winemaker's intention.

The "sawtooth" trends shows the impact of a pumpover, which unfortunately is not achieving good enough mixing. The wine at the bottom of the tank never reaches the desired set point and the skin cap reaches the setpoint for less than an hour before jumping.

While our real-time Brix readings are looking good as well (right side of the tank image), I know a lot of winemakers are changing their fermentation management based upon the MSP's ability to elucidate temperature at every level of the tank.

About

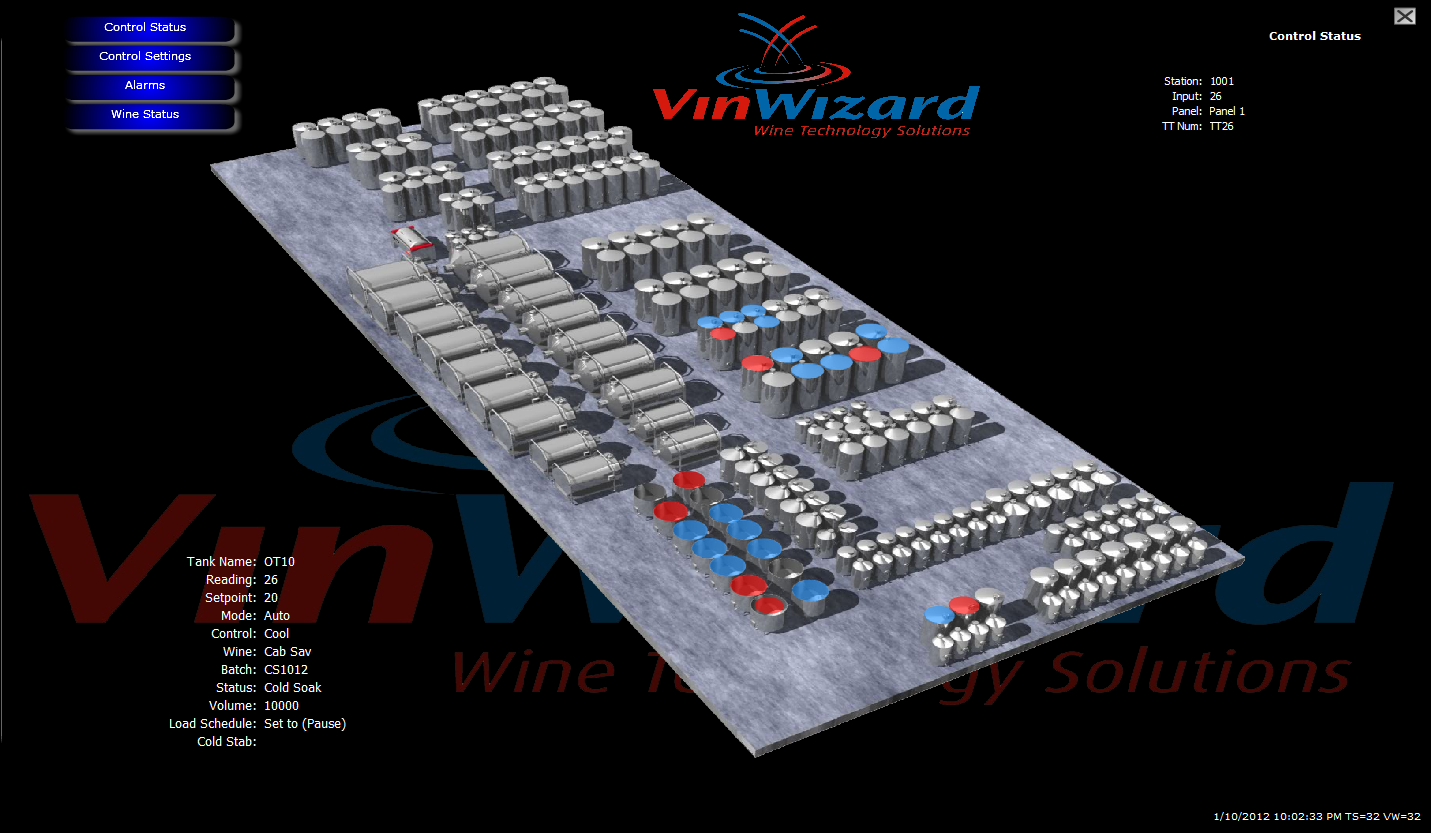

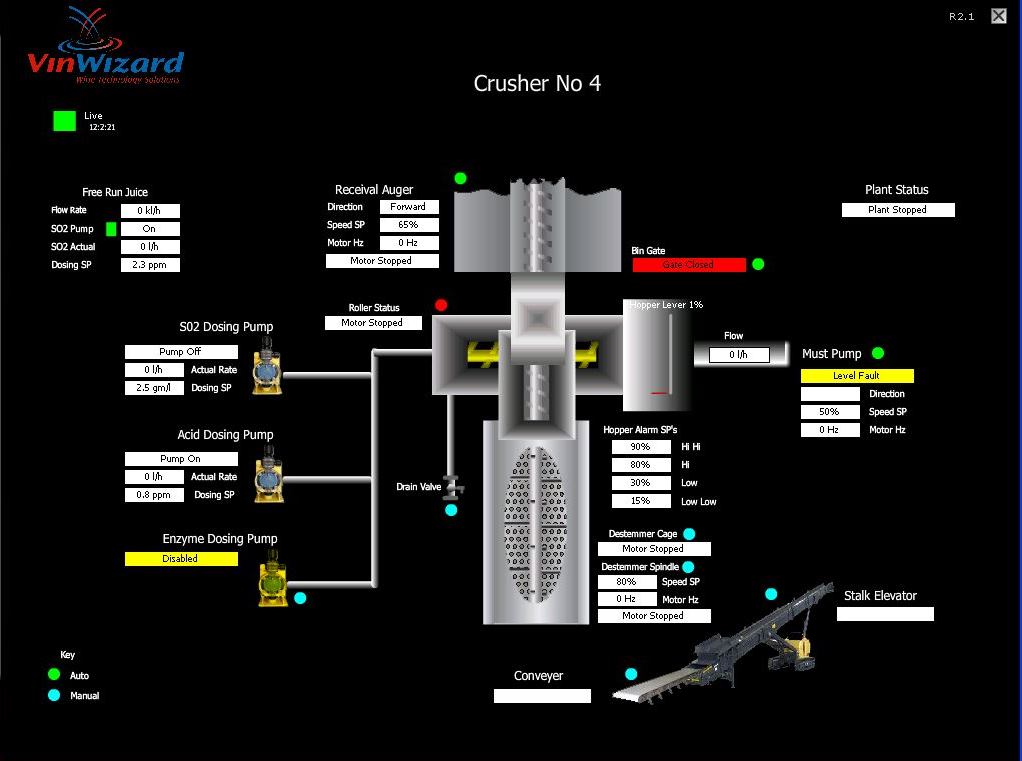

Founded in 1996 VinWizard is established as the default technology for next generation tank control and complete facility integration. Over 200 leading wineries around the world rely on the system to help maximise the potential of fruit entering the winery while reducing power consumption and staff requirements.

Operating a tank control system in isolation is no longer an option for wineries concerned with production cost and wine quality. Through integration with refrigeration plant and application of powerful software logic power savings of up to 50% are readily achievable. Wine is better protected with alarms raised at the source and not when tanks have suffered the impact. Refrigeration resources can be directed to the tanks that most need it and plant can be operated at an appropriate level according to load and power price periods.

Tank control is taken to new levels giving winemakers a greater understanding of what is actually happening inside the tank. Tank temperature control, automated pumpovers, air injection, headspace gassing and agitator control save labor, reduce mistakes and enhance the wine. In-tank sensors deliver on-line monitoring of temperature stratification, brix and redox with data readings triggering temperature changes, pumpovers and agitators. Integration with winery production software allows a seamless bi-directional exchange of data which can trigger temperature profiles in VinWizard and display data where most needed.

VinWizard Temperature Control Introduction

VinWizard Modules, Power and Water

Multi-Level-Probe Introduction

VinWizard Pneumatic Air Valves Introduction

Temperature control with single or multiple sensor options

Temperature control with single or multiple sensor options

Interface to refrigeration plant for control & energy savings

Interface to refrigeration plant for control & energy savings

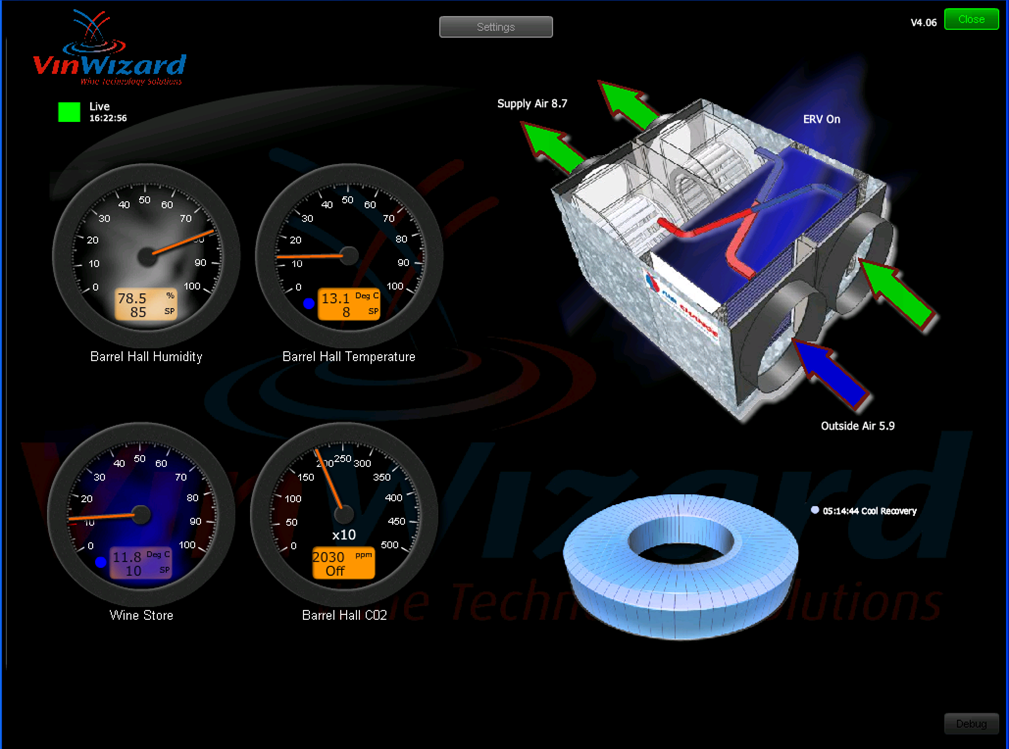

Barrel hall monitoring and control

Barrel hall monitoring and control

Contact

Contact List

| Title | Name | Phone | Extension | |

|---|---|---|---|---|

| Managing Director | Kelly Graves | kelly@vinwizard.us | +1 7202842059 | |

| COO | Robert Richards | bobrichards@vinwizard.us | +64 021731770 |

Location List

| Locations | Address | State | Country | Zip Code |

|---|---|---|---|---|

| Wine Technology Incorporated | 703 2nd St Ste 445, Santa Rosa | CA | United States of America | 95404 |