811 Live Oak Street, Tarpon Springs, FL, United States of America, 34689

Feeds

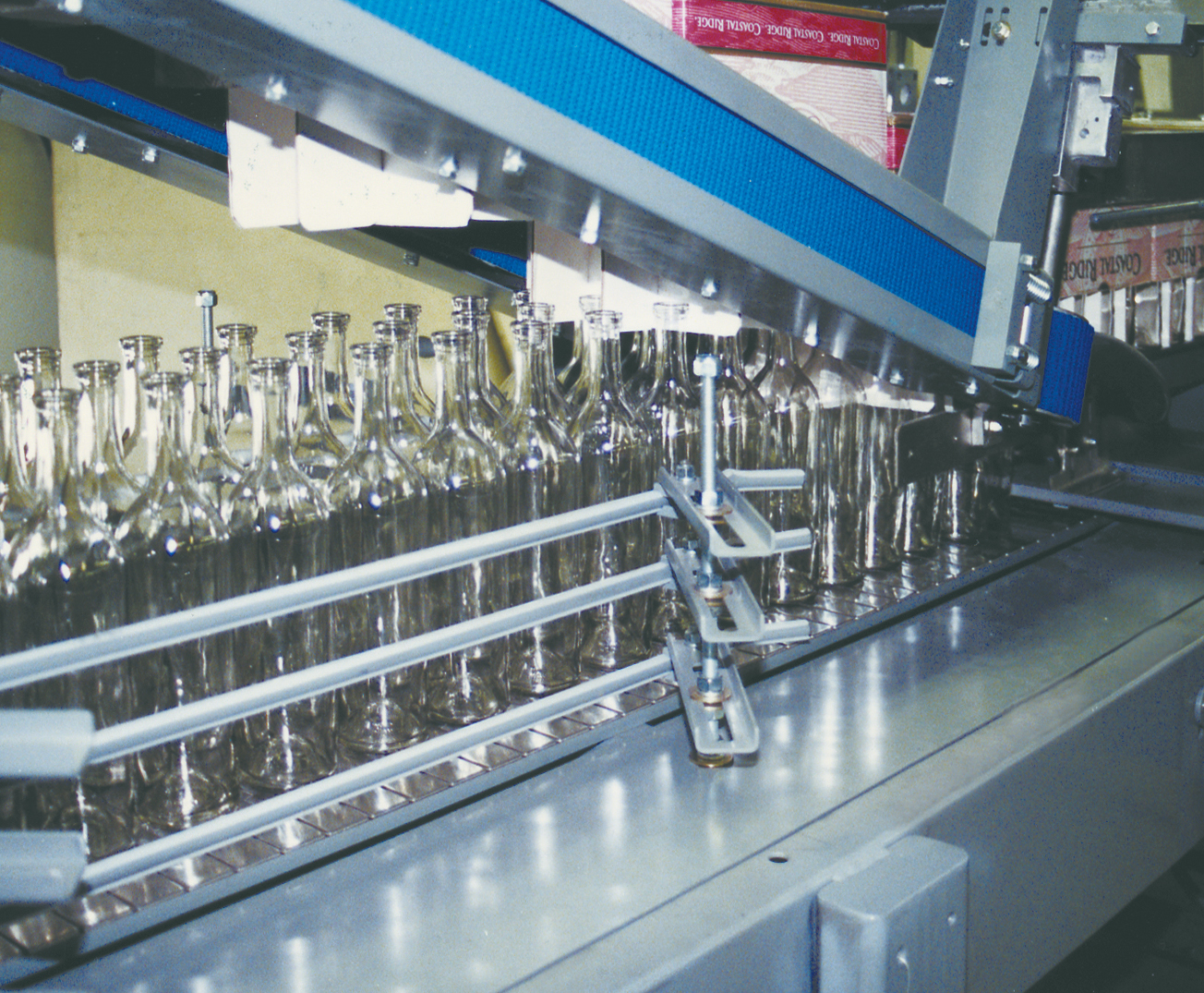

Decaser/ single filer for wine reshipper cases replaces manual dumping and increases line productivity from A-B-C Packaging

Wineries who receive their bottles in necks down reshipper cases can automate their hand dumping operation, reduce costs, increase line speeds, and ensure a consistent bottle supply to their filler with A-B-C’s Model 49  decaser. The Model 49 accepts cases from the conveyor either back-to-back or spaced, unloads and single files the bottles, and uprights the empty cases for transfer to case packing. Bottles glide from the case to

decaser. The Model 49 accepts cases from the conveyor either back-to-back or spaced, unloads and single files the bottles, and uprights the empty cases for transfer to case packing. Bottles glide from the case to

the impact-absorbing transfer belt and bottle contact is minimized with A-B-C’s unique single filing module.

These features work to maintain bottle stability and protect the glass integrity. By replacing the hand dumping operation, the decaser eliminates the related risk of employee injury from repeated lifting and

emptying of heavy cases.

The Model 49 has special features to accommodate case size variations, including a soft roller

system that utilizes an automatic tensioner to ensure smooth case transit throughout decasing. The 180-

degree case turnover securely holds the cases as they are oriented before discharge. The Model 49 runs

RSC, HSC, and RSC tablock cases at speeds to 50 cpm, and offers quick and easy changeover.

Pack Expo Southeaset

Event Type: Trade Show

Event Date: 03/10/2025

Location: Atlanta, GA USA

End of Line Packaging Solutions for Distilled Spirit Lines at Booth #802

End of Line Packaging Solutions for Distilled Spirit Lines at Booth 802

End of Line Packaging Solutions for Distilled Spirit Lines at Booth 802

A-B-C decasers provide fast and efficient reshipper unloading

Wineries who receive their bottles in necks down reshipper cases can automate their hand dumping

operation, reduce costs, increase line speeds, and ensure a consistent bottle supply to their filler with A-B-C’s  Model 49 decaser.

Model 49 decaser.

The Model 49 accepts cases from the conveyor either back-to-back or spaced, unloads and single

files the bottles, and uprights the empty cases for transfer to case packing. Bottles glide from the case to the impact-absorbing transfer belt and bottle contact is minimized with A-B-C’s unique single filing module.These features work to maintain bottle stability and protect the glass integrity. By replacing the hand

dumping operation, the decaser eliminates the related risk of employee injury from repeated lifting and

emptying of heavy cases.

The Model 49 has special features to accommodate case size variations, including a soft roller

system that utilizes an automatic tensioner to ensure smooth case transit throughout decasing. The 180-

degree case turnover securely holds the cases as they are oriented before discharge. The Model 49 runs

RSC, HSC, and RSC tablock cases at speeds to 50 cpm, and offers quick and easy changeover.

Click to learn more...

Packaging solutions at Pack Expo International booth N-5306

End of line Packaging Solutions for Distilled Spirit Lines at Booth N-5306

See 3 machines in operation:

- Automatic Palletizer with programmable Modsort conveyor

- Case Erector for low, medium or high speeds

- Case Sealer for tape or adhesive case sealing

For more information click here...

pack expo international 2024 pack expo pack expo chicago 2024

A-B-C's case sealers offer a reliable and cost-effective alternative to manual case sealing.

In an age when even packaging machines are disposable, A-B-C still builds case sealers that last, crafted from  heavy gauge steel with top quality components. For over 80 years, quality and performance have made A-B-C case sealers the industry standard for all your case sealing needs. Today we’re setting new standards with case sealers for your real-world production demands, today and in the future.

heavy gauge steel with top quality components. For over 80 years, quality and performance have made A-B-C case sealers the industry standard for all your case sealing needs. Today we’re setting new standards with case sealers for your real-world production demands, today and in the future.

- Small footprints for easy installation

- Servo or pneumatic flap tucker for secure flap closing

- Flexible compression rollers for well-sealed cases

- Designed for the most challenging case sealing requirements

- Run RSC, HSC, Bliss, and FOL cases

- Seal with tape or adhesive, at speeds from 10-75 cpm

Model 436 Adhesive sealing to 75 cases per minute

Model 436T Tape sealing to 50 cases per minute

Model 30 Adhesive top and bottom sealing to 50 cases per minute

Model 30T Tape top and bottom sealing to 50 cases per minute

Model 236 Adhesive sealing to 25 cases per minute

Model 236T Tape sealing to 25 cases per minute

Packaging solutions at Pack Expo Int. booth #N-5306

End of line Packaging Solutions for Distilled Spirit Lines at Booth #N-5306

For more information click here...

pack expo international 2024 pack expo pack expo international

Simple and reliable case erectors run less than perfect corrugated from A-B-C

Simplicity and reliability are the hallmarks of A-B-C case erectors. With heavy tubular steel frames and mechanical case drives, these workhorse box erecting machines ensure low maintenance operation and long machine life.  These erectors are built to excel in your real-world production situations, with exclusive features to keep your line running smoothly:

These erectors are built to excel in your real-world production situations, with exclusive features to keep your line running smoothly:

- Low level KD magazines ensure quick and easy refills

- Magazines designed to run warped and band-marked cases

- Positive case opening devices accommodate cases with off-spec manufacturers joints

- Walking beam case transfers square cases as they travel

- Simple and intuitive controls - full guarding with interlocks

- No-tools changeovers (auto changeover available)

- Models for RSC, HSC, FOL, Tablock, Integral Divider, Small & Oversized cases

Click here to see case erector video applications..

case erector case erectors case erecting box erector box erectors

A-B-C's depalletizers maintain total bottle control during layer transfer and discharge

Enjoy the accessibility of floor-level operation and the flexibility of low or high level container discharge with A-B-C sweep-style depalletizers. Fast and efficient, these quality depalletizers employ exclusive features to

ensure  reliable performance and carefree operation.

reliable performance and carefree operation.

Their clean, open profiles ensure high visibility on the plant floor. Designed with innovative features to maintain total bottle control during layer transfer and discharge,

and built for dependable long-term production, A-B-C depalletizers are a trusted solution for bottle handling productivity.

- Multiple features to ensure optimum container stability

- Efficient design and quality production features ensure reliable, high volume operation

- Run glass and plastic bottles, jars, metal cans and composite containers on one machine

- Run multiple sizes or containers interchangeably with no downtime or change parts

Model 108 Low level depalletizer

Model 108 High level depalletizer

depalletizer depalletizers depalletizer for bottles depalletizers for bottles

A-B-C decasers provide fast and efficient reshipper unloading

For fast and efficient reshipper unloading, A-B-C decasers are the solution. These versatile decasers do the work of three machines - flap opening, uncasing, and bottle single filing - in continuous, mechanical, high speed  operation. With over 50 years of proven production in the wine and distilled spirits industries, these decasers are a solid investment for any reshipper case operation.

operation. With over 50 years of proven production in the wine and distilled spirits industries, these decasers are a solid investment for any reshipper case operation.

- Eliminate manual labor and liability, and reduce production costs

- Maintain a consistent container supply to the filler

- Gentle handling for optimum container integrity and stability

- Uncase glass or plastic bottles from RSC, HSC, and RSC-Tablock style cases

M49 Bottle uncaser for rounds and ovals speeds 70 cpm

M156 Bottle uncaser for many styles speeds 50 cpm

Model 101U Robotic unpacker

M360 All-in-one uncaser and packer speeds 15 cpm

Compare models

About

Every day, A-B-C machines are hard at work; case erecting, packing, sealing, palletizing, bulk depalletizing, uncasing on production lines around the world. You can rely on us for quality machines that stand the test of time, supported by comprehensive service and support for the life of your equipment.

We’re working to help you meet packaging challenges today and in the future, with machines that offer greater flexibility, faster changeover, and wider product ranges, while making operation simpler and more intuitive than ever before.

We meld new technology with proven operating principles for machines that deliver real-world solutions for your packaging needs.

Contact

Contact List

| Title | Name | Phone | Extension | |

|---|---|---|---|---|

| VIP Sales & Marketing | Bryan Sinicrope | bsinicrope@abcpackaging.com |

Location List

| Locations | Address | State | Country | Zip Code |

|---|---|---|---|---|

| A-B-C Packaging Machine Corporation | 811 Live Oak Street, Tarpon Springs | FL | United States of America | 34689 |